Hi, I am John the sales manager here at MARS! This is one of my personal builds/ideas. Check it out!

We are beginning a project that I have had for many years now. Using a Corvette trans-axle to make a mid-engine vehicle! Of course, with the Corvette trans-axle design it is not very useful in most vehicles because of the axles coming out at the rear. The only thing I thought would work well would be a pickup truck.

THE DONOR TRUCK:

I picked up this 1986 C10 from the auction for $700 with a clear title out of Kansas. With a single cab and long bed it will be perfect to turn into a race truck! The long bed should have plenty of room for the engine, transmission, and Corvette rear carrier/suspension. Figuring it will fit the factory wheel wells.

After getting the truck back to our shop, we first stripped the bed off of it to check out the frame. The frame was in excellent condition and not rotted out like a local Ohio truck would have been. However from the photo’s at the auction we could not see the bottom of the doors were rotted out as well as the rockers and cab corners. Not a huge problem since we got the truck for $700.

THE C5 CORVETTE T56 TRANS-AXLE CONVERSION:

To make this work we took a spare C5 Corvette T56 rear cradle out of a car we had at the shop. We still however had no plan or idea for what engine would power this project.

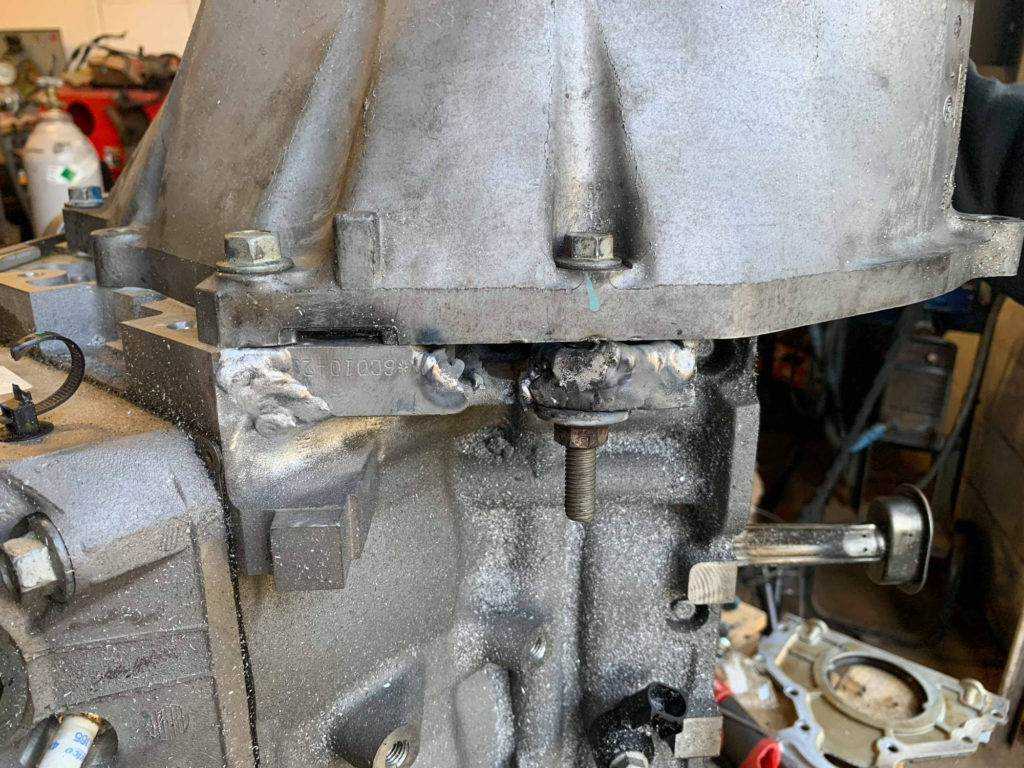

The Corvette T56 trans-axle will need to be modified for it to accept the LS engine directly to it in the truck bed. My thoughts are to change the front plate to an F-Body/GTO and then throw on a bell housing. There are tons of info on converting the Corvette T56 to a F-Body T56, so that helps a bunch. The next piece of the puzzle is to figure out a shifter option to shift the transmission since it will be in the truck bed. We are thinking about using a FWD manual shifter with cables to control the shifter at the “mid-shift” location.

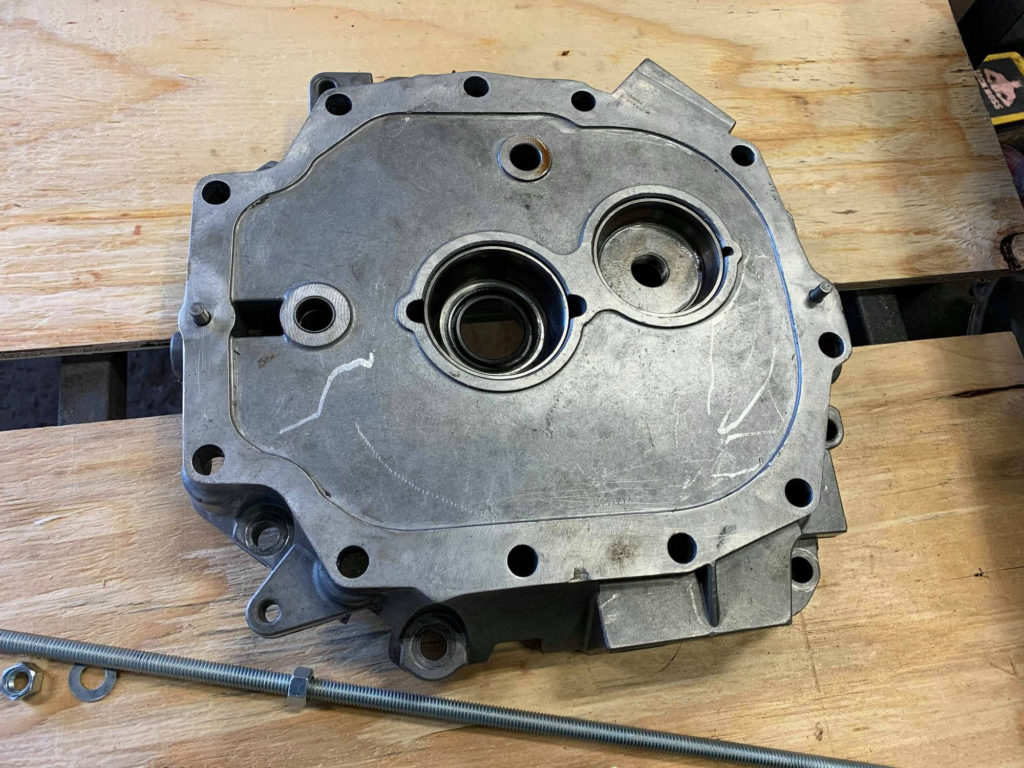

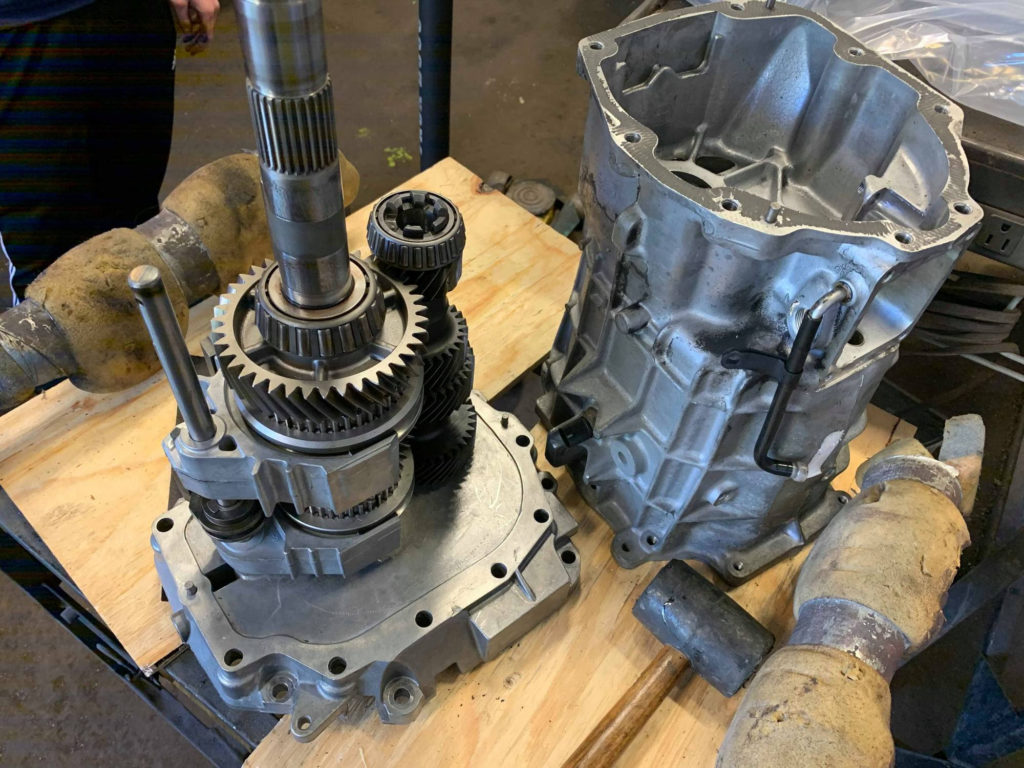

I got the Corvette T56 all stripped down.

After getting the transmission stripped down I began looking for a core F-Body/GTO T56 to steal parts from to change the front cover and bellhousing. Another thing needing to be changed is the shift rail. The Corvette T56 shift rail sticks out of the front cover to run along the top of the torque tube to the Corvette shifter. The F-body/GTO shift rail will stick into the carrier area. Only thing to do is chop off the rear of the F-Body/GTO rail.

I purchased a McLeod mid-shift shifter receptacle. (McLeod PN: 82-1001) This is going to give me an option to shift the transmission.

Next I finally found a cheap core GTO T56 that I could steal the front plate and bell housing from. It came from a heavily damaged GTO… and while the T56 was an upgraded RPM Transmission’s T56, more than just the rear housing was destroyed. (the seller said the bell housing and such was fine, just small crack in the rear housing)

I ended up just purchasing a new front plate and bellhousing elsewhere and selling this T56 for a loss to my friend.

Still no idea on an engine for the project yet either.

A YEAR LATER…

I guess after the loss on the T56 and the frustration the salvage yard gave me over not returning the T56 left me a bit bummed and I lost focus on the project.

Anyhow, we pick up with me purchasing an additional shop to get some projects done.

Finally having a garage big enough for a few of my projects, brought back some spark to get the ball rolling on the Mid-Engine C10 again. With the first time since I purchased the truck it was under roof and at my new shop.

First thing was to finish the T56 conversion. My biggest fear was shimming the main shaft and counter shaft, but after actually starting on a Saturday morning and finishing it was quite simple if you follow the instructions. I had bought the complete shim pack from Hawks.

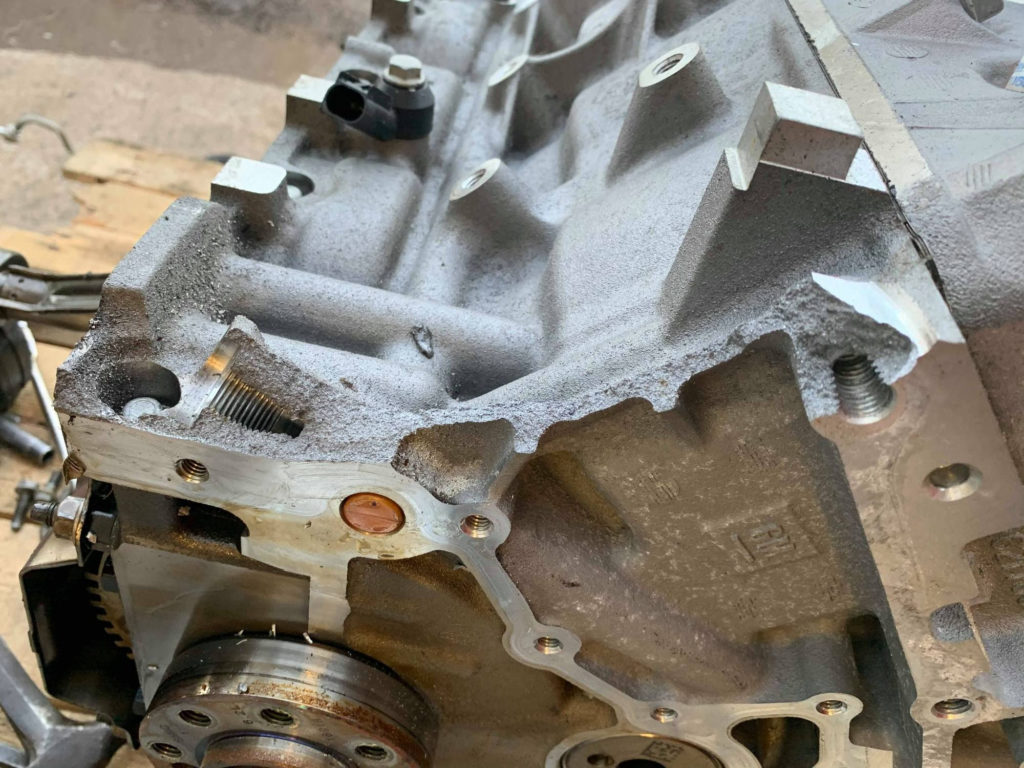

Following several YouTube videos and diagrams we got the T56 assembled with the front half being F-Body/GTO and the rear half being Corvette.

THE POWER PLANT

Earlier this year we purchased an 2012 CTS-V in hopes to get a few parts needed for another project. This left us with a spare LSA block and well not much else…

The engine spins freely, however the rear left corned got fractured from the accident. The damaged did not appear to go deep and we opened the bottom end up to inspect for further damage before deciding we would give it a go.

The chunk that was fractured off was just were the bellhousing bolts on to the drivers side. We went ahead and knocked it off the rest of the way to begin the repair.

I plan on using this throttle body, reverse mounting a Holley High Ram intake, and using a Shearer Fabrications Holley High Ram intercooler adapter fed by twin turbos to complete the power plant. I would like to run the new Precision Turbo symmetrical turbo’s for an ultra clean appearance, however I think their size options are going to be too big for my use. I plan on using this truck as a road coarse/autocross race truck.

10/17/2019

We got our mid-shift shifter from the Summit Racing Discount Rack! Check it out in the video below!

This past Saturday we spent our time removing the front suspension out of the C10 as well as the rear axle and leaf springs. We wanted to get the frame bare other than the cab so we could wire brush and paint it. The front suspension unbolted nicely and we were able to test fit the C5 Corvette front suspension. The test fitting was nice and we got our first look at the 2017 Camaro 1LE wheels matched up to the ’86 C10. They look amazing and I think will do us mighty fine for racing.

Next we got to work on removing the rear axle. Even with how clean the frame and overall truck was, the leaf spring bolts gave us a long fight. We ended up just cutting the hangars with a sawzall since we were not going to be using them anyhow. I then spent the next Sunday afternoon grinding the rivets off to remove the leaf spring hangars. The frame cleaned up extremely well with a quick wire brushing that Luke helped out with. We were able to accomplish a lot over this past weekend!

After spending about 2 hours going over the frame with the wire brush and a quick run over to Oreilly’s for some paint we put on the first coat. The rain from throughout the day had finally stopped but with the temperature slowly dropping that evening the paint took forever to dry.